Printed Circuit Boards

In the past I have had some success with KiCad and have had boards made at OSHPark which do look lovely. Recently I was made aware of EasyEda, an on-line PCB design tool which (apparently) is easy to learn and easy to make FootPrints with – one of my difficulties with KiCad is MY ability to locate and use customised footprints for Nixie Tubes.

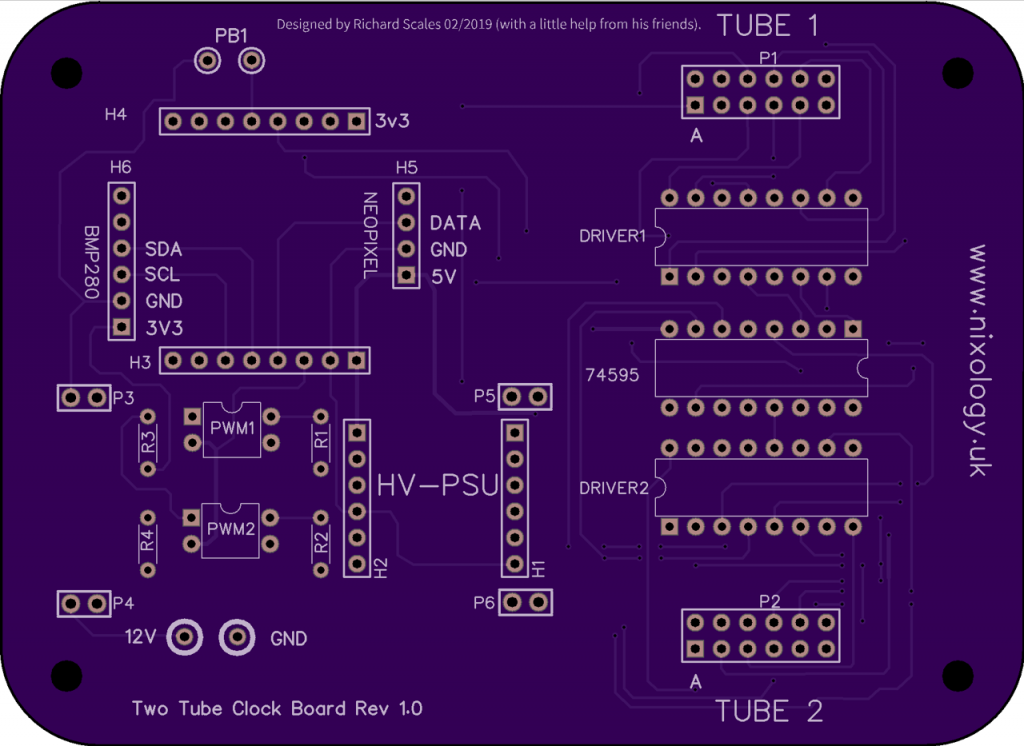

At the same time, I received an offer to have my Two Tube Clock prototype laid out on a PCB using EasyEda by another member of my support group. This resulted in me checking PCB layouts against original schematics until it was deemed ready to commit to a trial prototype run.

During this process I decided to force myself to learn how footprints are made and how they are tied to schematic symbols to make usable components.

It actually turned out to be quite straight forward, especially as lots of people have already created similar parts which I was then able to modify for my own use. One example being a B13D tube base, whilst the position of the pins remains fairly constant across all the different types of tube that use this arrangement, the actual pin designations can change depending on whether or not the is a left hand and/or right hand decimal point, the placement of the Anode(s) and the order of all the cathodes.

I had some GNP-7A tubes that I had recovered from some other equipment and making them fit ‘generic’ tube cell adaptors was probably going to end up in broken wires and tears. So I created a footprint that looked for every pin exactly where it should be, no bending or cutting of fragile short leads required.

Having created something that looked half right I then went on to repeat the process for some HiVac XN-12’s that I have been collecting over recent months. I have a mixture of NOS tubes as well as several that have been recovered from PCB’s though in the case of the HiVac’s then leads are quite long still. Regardless, in the pursuance of the non-breakage of leads, a new tube cell adaptor has been designed.

As we speak, skilled operatives are making 10 each of each type of adaptor as well as 10 prototype boards for my Two Tube Clock. For this service, including shipping to me in the UK, I had to part with 12 USD. This is surprisingly little for the number of parts involved. A full report shall be forthcoming once the boards are in.

In contrast, OSHPark wanted over 55 USD for only three PCB’s for the Two Tube Clock alone. That being said, they would have been (I expect) of better quality, thicker PCB, Gold plated and very purple!

Recent Comments